When my mom was a little girl, she lived in Guatemala, in a city named Xelaju (Shayla- Who). It was a significant time in her life because it was the first place she was able to go anywhere by herself. She was allowed to take a taxi to and from her ballet class.The city was still called Xelaju, or just Xela by the locals, even though the Spanish conquistadors changed it to the more widely known name of Quetzaltenango, after the colorful national bird of Guatemala. I’ve not been there, yet, but I’m told my name is on the city buses, and there is still a part of the area called Xela.

My parents changed the spelling to Shayla. I gratefully joke that was so the mean kids wouldn’t call me “Exlax”! My family sometimes call me Shayla-who, and I love that. In more recent years I have heard of other Shayla’s, even one spelled Xela by her father who had lived there. A couple of years ago, I even met another Shayla in person, but so far none of them have been older than me, so I am still “The Original”.

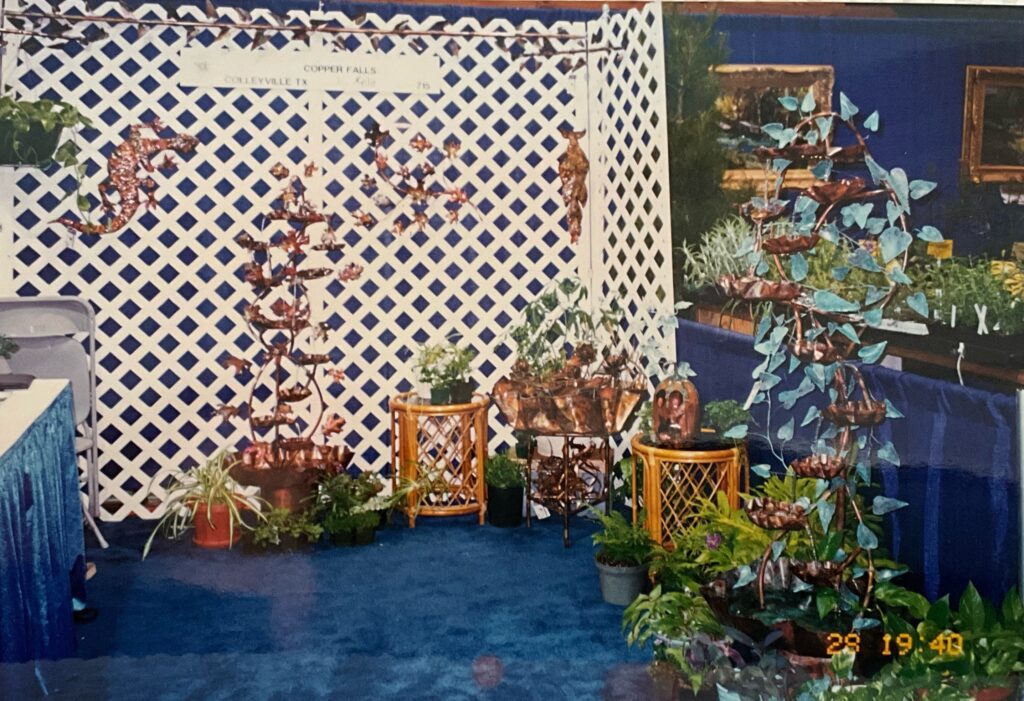

This was the beginning of Copper Falls by Xela. I had begun to learn metal sculpture in 1987 from Ceil Whitebrook. I later joined her in Asheville, NC and New Smyrna Beach, FL for an apprenticeship. I used an oxy-acetylene torch and copper or brass sheets and tubing to create mostly fountains and some wall art. This is a picture from The Neil Sperry garden show in DFW in maybe 1997. A man walked in and said, “You didn’t make this!” I assured him I did but he would not believe me.Another time I went into a welding supply store to find the copper/nickle brazing rods. I asked for something specific and the guy asked me, “What does your husband need it for?” 🙄

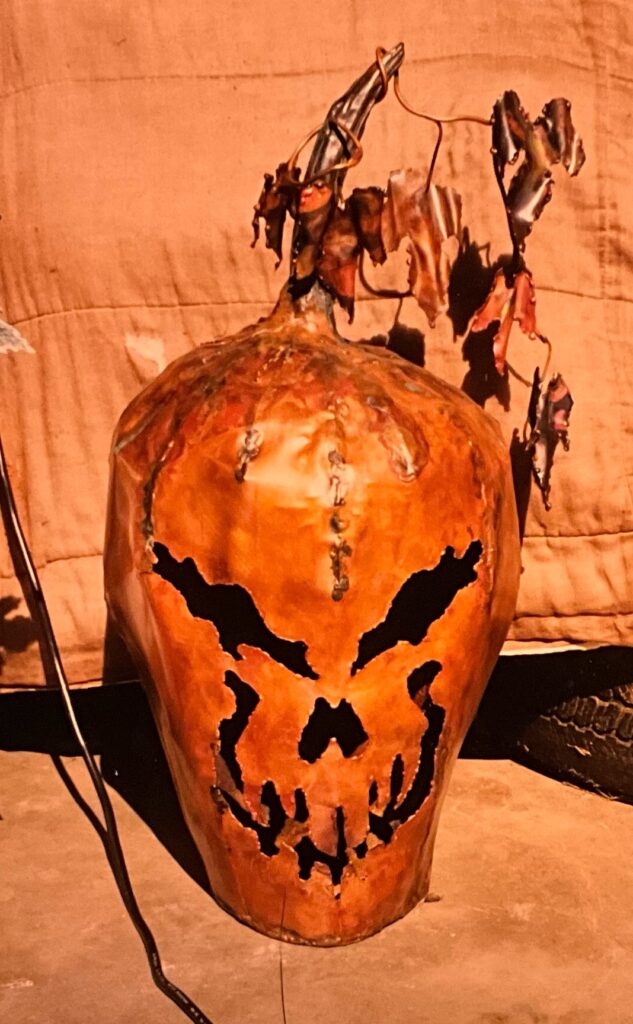

(UPDATE: Found them!) Somewhere I have pictures of my work in copper. A big thanks to friends and family who were able to send me some pictures. I mostly made fountains from small tabletop size to really large freestanding ones. One of the things I loved about working with copper was cutting most of the pieces with the oxy-acetylene torch. The heat turns the copper a rainbow of colors. The trick is knowing when to quench it in water for the desired colors. The fountain in this photo has red water lilies. That red was tricky. I had to get the metal super hot and dunk it in the water immediately. It was also hot enough to burn holes in the copper so timing was essential. Then came the trickier part of brazing the pieces together. Hot enough to melt the alloy but not so hot it changed the color. I had achieved. I also love the look of burned edges. I would go back over every cut to be sure there were no sharp edges. You can see edges in the close up of the angel.

Above: Fountain installed in home. Right: Fountain in progress.

My booth at a home and garden show.

You can follow my Instagram @copper_falls_by_xela

https://www.instagram.com/copper_falls_by_xela?igsh=eXV6a2MwemQ1cTcy

Or on Facebook